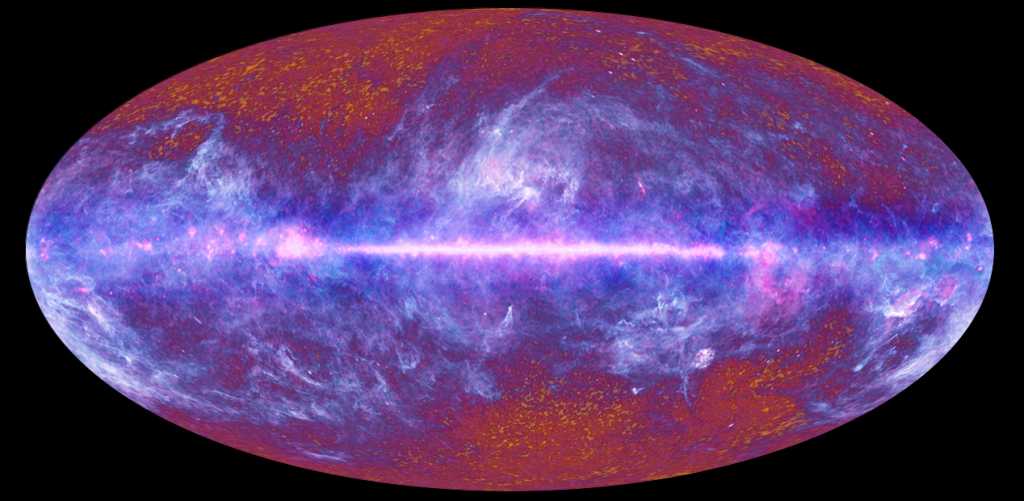

Subject Matter Experts (SMEs) in semiconductor and in-space manufacturing collaborated on a white paper that outlines how microgravity benefits the production of semiconductors and related materials. Earth’s gravitational forces pose substantial barriers to quick, high-yield semiconductor production. Microgravity offers a path to overcome these barriers. There are also substantial practical benefits to incorporating LEO-based manufacturing into the supply chain. The white paper argues that transitioning this industry into space is a path forward to achieving NASA’s In Space Production Applications’ (InSPA) goals. These goals include strengthening U.S. technological leadership, improving national security, creating high-quality jobs, providing benefits to humanity, and enabling the development of a robust economy in LEO.

The paper, “Semiconductor Manufacturing in Low Earth Orbit for Terrestrial Use” can be found here.

Additional information on NASA’s InSPA portfolio can be found at: